Tired of Road Tubeless

Ben Sharp Technical England 01 November 2018

Read a review of any new road wheelset and it will likely be labelled as “Tubeless Ready” or “Tubeless Compatible”. The technology has been in use for years in Mountainbike and Cyclocross. It seems like a no brainer to move the tech over to road bikes and exploit the benefits of tubeless technology. But like a lot of new cycling technology you need to dig a little deeper, take a moment to really consider if it’s right for you. Ben Sharp of Sharp Precision Wheels tells us the other side of the story of road tubeless technology.

Read a review of any new road wheelset and it will likely be labelled as “Tubeless Ready” or “Tubeless Compatible”. This is essentially a new wheel/tyre interface, not to be confused with the use of tubular tyres (where the tyre is physically glued to the rim). In the road tubeless system, tyres are run without an inner tube, and the interface of the tyre bead and rim are tight enough to prevent a tyre from blowing off a rim. To achieve a tight seal rim beds are taped and a liquid sealant is used to ensure no tiny imperfections or holes cause a loss of pressure. The technology has been in use for years in Mountainbike and Cyclocross, allowing tyres to be run at very low pressures for increased traction in muddy conditions, and meaning that small piercing punctures caused by thorns and the like are sealed almost instantly. It seems like a no brainer to move the tech over to road bikes and exploit the benefits of tubeless technology. It would be seen as suicide for a manufacturer to release a rim that isn’t “Tubeless Ready” now, and recent reviews are full of glowing praise, but like a lot of new cycling technology you need to dig a little deeper, take a moment to really consider if it’s right for you.

As far as road tubeless technology goes, I don’t think the other side of the story is being told fairly. As a rider who has tried the system, but also someone who works with wheels every day, building different combinations of parts and trying to understand how all the various components of a wheel work, I am well placed to explain why I think the technology isn’t appropriate for high pressure rim-brake road bike applications, with smaller tyres, and offer some balance to the praise in recent reviews. This might at least enable riders to make a balanced decision about whether to adopt the technology.

I don’t want to put a total negative on it: any new technology will be alien to the first adopters, and innovation is key to pushing bicycle technology forward, but if the drawbacks outweigh the benefits, and we cause more problems without solving ones already created, then aren’t we better off focussing our innovation elsewhere? With very little in the way of industry standards for road tubeless technology, it feels like a lot of R&D is being done by the consumer. For me the problems fit broadly into two categories:

1. Day to day life with the wheel

Firstly, tyres are incredibly tight on a tubeless ready rim. Since there is no physical inner tube to push the tyre bead into the hook of the rim, it is the structure of the tyre that is responsible for making sure it can’t blow off the rim. This presents a major problem in day to day use for the average rider. I’ve got enough experience to fit most tyres without a tyre lever, but when it comes to tubeless tyres you are going to have to use a fair bit more force and technique when fitting the tyre. This is all well and good in the comfort of your own home, but imagine you’re out on a ride, 60 miles from home in the cold and wet, desperately trying to get a tyre off with frozen fingers, sealant sloshing all over your kit and bike. The extra hassle with the tyre is worth it if you can go out on a ride and not worry about punctures, but tyres don’t seal as well at high pressure as they do at low pressure, and most of the serious punctures you’ll suffer like slashes from glass fragments won’t be helped by running a tubeless tyre. It just means that when you do suffer a proper puncture, it’s going to be twice as hard to repair. Furthermore, the harder the tyre is to install, the greater the likelihood of riders using large tyre levers and damaging lightweight rims through excessive force.

Couple this with the fact that you’ll be needing to remove tyres every 3 or 4 months to replace the sealant so that it remains effective, and you’ve got an ongoing maintenance situation that most cyclists would be less than impressed with. I’m not saying riders aren’t interested in maintaining their bikes, but generally speaking we prefer a simpler, hassle-free experience.

2. Performance of the wheel

This is where my experience as a wheel builder comes in to analysing the effect of road tubeless tyres on the wheels I build. Road cycling rims have been getting lighter and lighter over the last few years, largely driven by consumer demand for lighter and lighter wheels. We’ve now reached a point where aluminium and carbon rims are pretty much as light as they can possibly be. Only 5 or 6 years ago, a 480g aluminium rim would be considered adequate for most road riders. Now we have wider, deeper profiles at around 430 grams. The only way this is possible is by reducing the wall thickness of rims. In Isolation this is a good thing: wheels with a lower rotational mass accelerate quicker and are easier to grind uphill. If the safety of the rim is not compromised, the performance gain is worthwhile. However, road tubeless tyres exert a far greater pressure on a bicycle rim than a traditional inner tube setup. In a market where rims have been getting lighter for years, they actually need to be heavier and more robust to deal with road tubeless tyres effectively. The real-world effect of the tighter tyres is a massive drop in spoke tension caused by the tyre’s compression on the rim. Almost twice as much of a drop when compared to using traditional inner tubes and clincher tyres. This leads to a reduction in stiffness of any wheel running tubeless tyres: a definite performance disadvantage.

In the case of 11-speed rear road wheels on 130mm rim-brake bikes, the effect is especially serious due to a compounding of problems. When we switched to 11-speed road groupsets, hub design was compromised. The drive side hub flange was shunted inboard to provide space for the extra sprocket, and this in turn led to a change in spoke angles and overall stability of rear wheels, meaning that the maximum achievable non-drive-side tension on 11-speed rear wheels was reduced. This creates big problems for high performance spokes such as the Sapim CX-Ray or DT Swiss Aerolite, which require a high tension for them to do their job of stabilising the wheel and transferring torque. These spokes now sit at the very lower end of their permissible operating tensions when built on a regular, symmetrical rim. Add the tension drop associated with a tubeless tyre into the mix, and they are simply not able to do their job properly. We’ve created a wheel stiffness design issue for road bikes and without solving it, compounded the problem by reducing the tension further still. The trueness or tolerance of any wheel will change as soon as a tyre is inflated on it, but the increased pressure of a tubeless tyre and the lowering on tensions below their operating minimums will send the wheel further out of true when compared to a traditional clincher tyre and inner tube.

Is there a solution?

If tubeless technology is to be optimised for road bikes and not have such a negative impact on performance, we need to increase overall spoke tension and stability in wheels. The problem isn’t as bad on disc-brake bikes, where the increased spacing at the rear of the bike enables a hub design which promotes better spoke tension. Why not change the axle standards on rim-brake road bikes? If rim-brakes are going to stay with us long-term, then the problem is only going to get worse as we move to 12/13/14 speed bikes and compromise hub design further to accommodate extra gears. Maybe a radical change would help: a 142mm thru-axle rim-brake road bike? High performance spokes could then be built at sufficiently high tension for them to be working properly regardless of the tubeless tyre compression, bringing stiffness and stability back to the tubeless ready wheel.

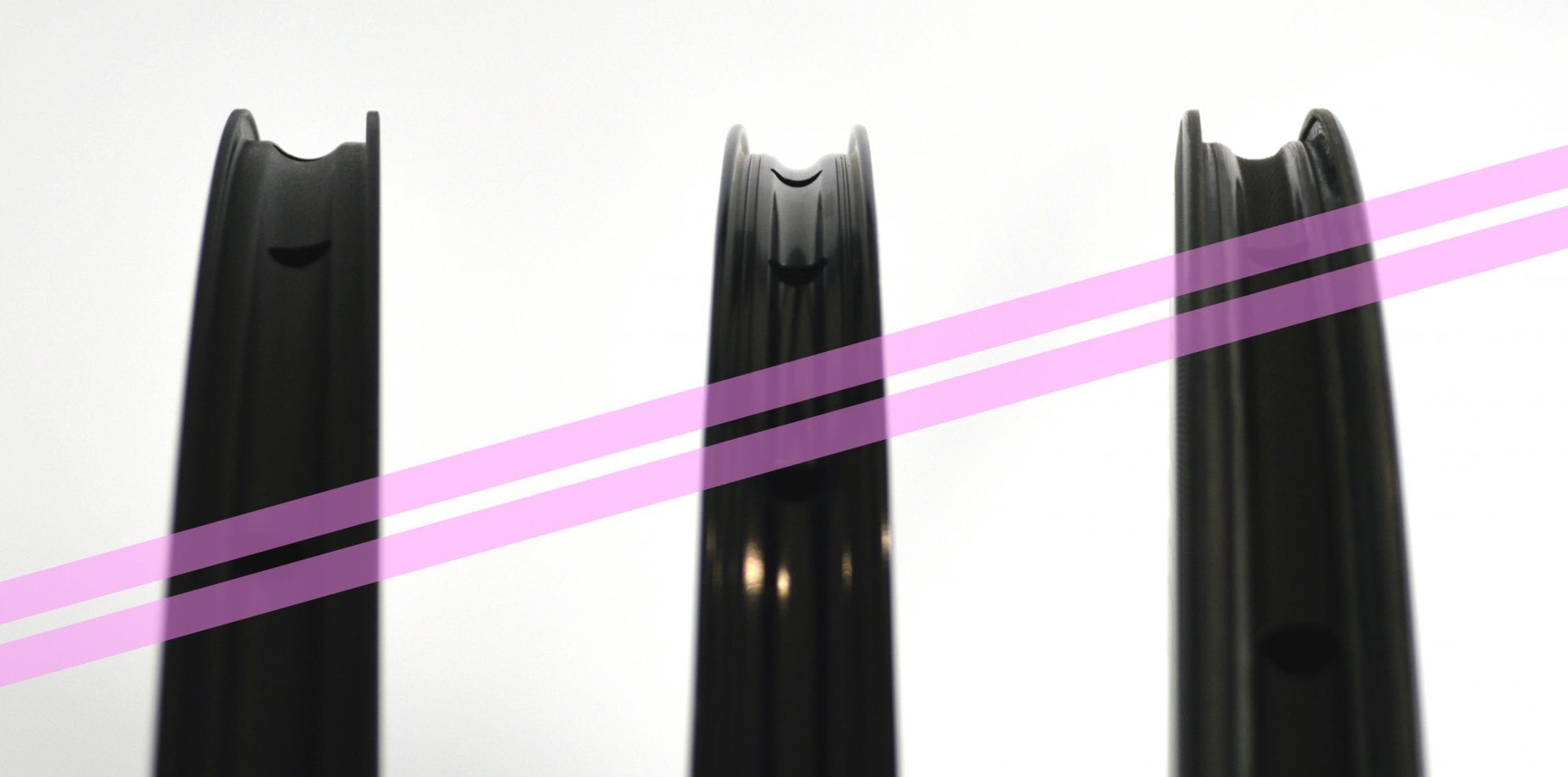

Rims probably need to get a little heavier, or at least design needs to change, either to increase the rims resistance to crushing by the tyre, or perhaps a shift towards more radically asymmetrical rims: which again help to re-balance non-drive-side tension and increase the stiffness of the wheel.

It is possible to use a thicker gauge spoke to help maintain stability at lower tensions and improve resistance to the spoke tension drop caused by tubeless tyres. Such spokes have a “minimum operating tension” which is typically lower than spokes like the CX-Ray. However, many riders won’t be happy with the added rotational mass in the wheel and the detrimental ride characteristics of a thicker spoke. The unique combination of comfort and zingy acceleration that comes from using thin, bladed spokes at high tensions is one of the things that makes a hand built wheel so attractive, and it will be a quality which is hard to surrender.

With manufacturers such as Continental now finally entering the tubeless market, and committing resources to establish an industry standard, it is also possible that we will start to see the whole interface becoming easier to use. Establishing firm dimensions for rims would provide a solid base for tyre development and help to eliminate compatibility issues between certain tyre and rim brands.

Ultimately, until some of these problems are solved, it’s hard for me to wholeheartedly recommend road tubeless to everyone purchasing wheels from me. While it works for some people, it isn’t suitable for everyone. Manufacturers need to do more in research and development to better understand how their products work in the real world. By not solving design problems we have already created, we can’t fully exploit the potential benefits of new technologies. Road tubeless tyres are one such technology. Until we solve problems to improve wheel stiffness and make the system easier to live with for the average rider, then the marginal benefits in rolling resistance and puncture resistance are outweighed by the negatives. In the meantime rims are only getting wider: reducing the tyre pressure you need to run inside a standard clincher, providing some of the benefit of a tubeless tyre.

It would be crazy for me to pretend that the market isn’t headed in a tubeless direction. Being not only a wheel builder but also a rider, I feel I have a duty to put forward both sides of the tubeless argument so that my customers can make a more informed decision about adopting the technology. Bigger tyres at lower pressures (Gravel, CX and MTB) all work well tubeless, but the smaller the tyre, and the higher the pressure (particularly on rim-brake road bikes), the fewer benefits there are.

-

Sharp Precision Wheels

Visit site